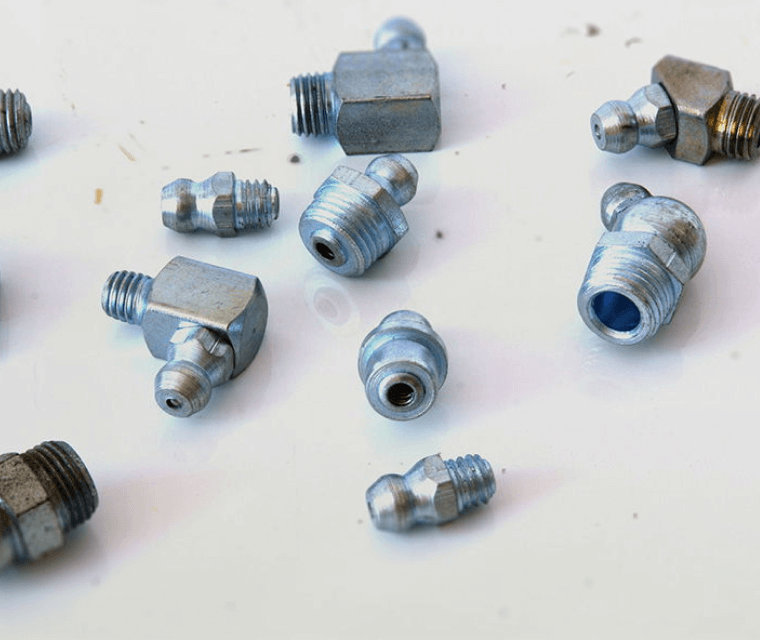

Union Fasteners provides various Surface treatment processes which can be applied to fasteners to improve their durability, corrosion resistance, and aesthetic appearance such as Natural Finish, Phosphated, Electroplating (Trivalent & Hexavalent) with green, white, yellow & Black Passivation, Blackening and more.

Union Fasteners also offer Nickel plating, Zinc flake coating (Magni, Geomet, Dacromet), Hot deep Galvanizing and more.

We strive for continuous improvement through productivity and employee participation.

We are committed to satisfy the needs and expectations of our customers by manufacturing and supplying High Tensile Fasteners & Stainless Steel Fasteners of stated quality, timely delivery and reliable services at all times.

We make sure each and every product face rigorous inspection stages the production process before they make it to the box, ready for shipment.

| Type | Descriptions | Reference Standards |

|---|---|---|

| High Tensile Standard Fasteners | Hex Bolts & Screws etc.. In metric & Inch Standard | S 1364-1 / IS 1363-1 / IS 1364-2 / IS 1363-2 / ISO 4014 / ISO 4016 / ISO 4017 / ISO 4018 / ISO 8765 / IS 13725 / IS 13726 / BS 84 / BS 916 / BS 1768 / DIN 558 / DIN 601 / DIN 931 / DIN 933 / DIN 960 / DIN 961 / DIN 6921 / ANSI B18.2.3.1M / ANSI B18.2.3.2M / ANSI B18.2.3.3M / ANSI B18.2.3.4M / ANSI B18.2.3.5M / ASME B18.2.1 |

| Nuts | Hex Nuts, Flange Nuts, Slotted Nuts, Castle nuts, Weld nuts, Square nuts, Lock nuts etc… | IS 1364-4 / ISO 4032 / ISO 4035 / DIN-934 / DIN-980 / DIN-939 / ANSI B18.2.4.1M / ANSI B18.2.4.2M / ANSI B18.2.4.4M / ANSI B18.2.4.5M / ANSI B18.2.4.6M / ANSI B18.16.3M / ANSI 18.2.2 — Special Nuts as per customer drawings & technical specifications |

| Studs | Standard Stud, SS Stud, Special stud etc | IS:1862 / IS : 2232 / DIN-835 / DIN-938 / DIN-939 — Special Studs as per customer drawings & technical specifications |

Chemical Compositions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | Material Similar | C Max | Mn Max | P Max | S Max | Si Max | Cr | Ni | Mo |

| A2 / B8, A4 / B8M | AISI 304 | 0.08 | 2.00 | 0.05 | 0.030 | 1.00 | 17.00 - 20.00 | 8.0 - 13.0 | - |

| AISI 316 | 0.08 | 2.00 | 0.05 | 0.030 | 1.00 | 16.00 - 18.50 | 10.0 - 14.4 | 2.00 - 3.00 | |

Physical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | Standard | Property Class | Tensile Strength Min. (N/mm²) | Yield Strength 0.2% Offset Min. (N/mm²) | Elongation After Fracture AL mm Min. | ||||

| A2 & A4 | ISO 3506 | 70 | 700 | 450 | 0.4d | ||||

| 80 | 800 | 600 | 0.3d | ||||||

| Grade | Standard | Property Class | Diameter In. | Tensile Strength Min. (KSI) | Yield Strength 0.2% Offset Min. (KSI) | Elongation In 4D min. % | Reduction Of Area Min % | Hardness (Max.) Rockwell |

|---|---|---|---|---|---|---|---|---|

| B8 B8M | ASTM A193 / A193M | Class 1 Class 2 Class 1 Class 2 | All | 75 | 30 | 30 | 50 | B96 |

| To 3/4 | 125 | 100 | 12 | 35 | C35 | |||

| Over 3/4 to 1 | 115 | 80 | 15 | 35 | C35 | |||

| All | 75 | 30 | 30 | 50 | C96 | |||

| To 3/4 | 110 | 96 | 15 | 45 | C35 | |||

| Over 3/4 to 1 | 100 | 80 | 20 | 45 | C35 |

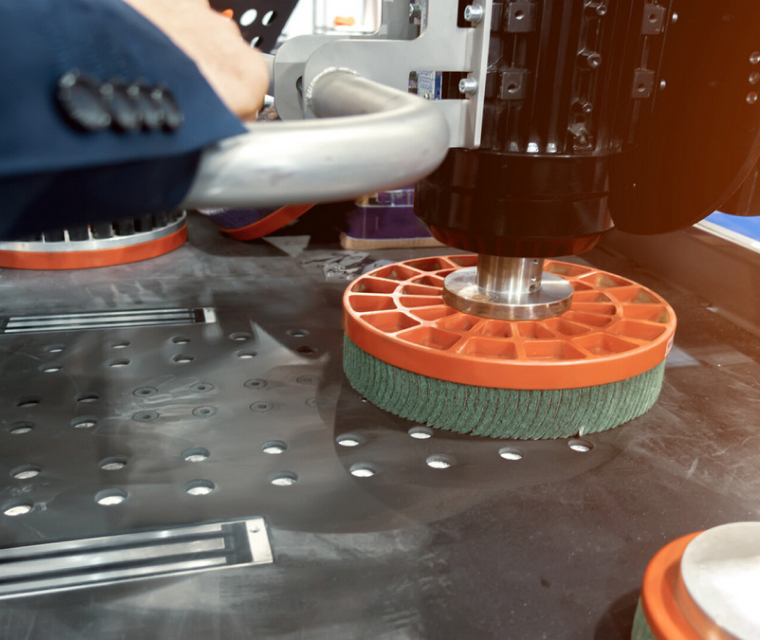

Surface Treatment